Consulting on all aspects of your transport logistics

Our service for optimization of your logistics processes

Shifted delivery volumes over the years, changed customer structure, relocation of depots or opening of new warehouses – these are only a few examples of why delivery structures should be reviewed and reconsidered and route planning should be optimized. Otherwise, the resulting insufficiencies inevitably lead to wasted optimization and, with it, savings potentials.

Through our transport logistics consulting, such questions can be analyzed and optimized with strategic planning using the PLANTOUR route planning software. Separately from expanded use of the tool, a strategic analysis and a simulation of scenarios requires modeling of data. The preparation of the database for such analysis can quickly become complex.

We support you with our transport logistics consulting with analysis and optimization of your transport processes – whether it’s about route planning, location optimization, or general questions such as your own vehicle fleet versus make-or-buy. In collaboration with you we develop a result that puts you in a position to decide based on facts and to gain cost savings as well as increased quality and productivity.

Increase in productivity

Higher quality, fewer costs, better plans and therefore relaxed employees. All of these factors affect your overall productivity positively.

Cost reduction

Too many driven kilometers, waiting times or unnecessary overtime as well as excessive wear and tear – reduce your cost drivers by optimized transport planning.

Improved quality

Realistic planning that reflects your actual transport requirements and increases your quality. Both, in internal processing and in customer service.

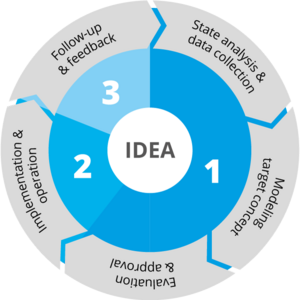

Project workflow of transport logistics consultation

We have developed a standardized workflow model during our many transport logistics consulting projects that gives us the tools to meet your requirements quickly. We differentiate between three project types that build on one another:

- Feasibility review: You have an idea and would like to check whether it could work? We prepare a feasibility analysis for you with our expert tools.

- Implementation concept: A potential for success was determined for your idea and now you want to implement it? We develop the concept together with you until it is ready for operational implementation.

- Adjustment: Even the best plan can be improved by customer feedback, drivers and dispatchers. Together we revise the plan on the basis of the received feedback.

You decide – even within the ongoing analysis – how far the project should go.

Understanding

You present your idea to us. To be able to picture the requirement correctly, we have to understand your current status and the desired target situation clearly.

Collection of data

We will work out which data are required for the analysis and how they can be collected. For the most part historical data is sufficient.

Data modeling

We model the representative database for your target concept by using our statistical methods.

Concept modeling

In the next step, we generate your current status situation in our expert tools such as PLANTOUR.

Modeling of the KPIs

By modeling the mutually specified KPIs, the potential of your idea can be measured easily and shown clearly.

Optimization of the KPIs

We compute the key characteristics of your current and your new concept. We optimize your model this way in order to achieve your desired optimum as much as possible.

Discussion

We discuss and review the plausibility of the result with you on an operational level. Your feedback becomes part of the presentation.

Presentation

We present the results, show you the facts and interpret them together with you. The decision for implementation is, of course, yours to make.

Documentation

You will be given an individual summary of the analysis results.

Interviews

Implementation often fails because not all requirements are gathered or the human factor has been forgotten. We support you with interviews of key persons in the field.

Optimization

If some aspects have not been taken into account sufficiently, we subsequently tighten up your new concept and adjust it.

Implementation concept

We develop a realistic implementation concept from the gradual shift to the optimal point of time.

Data feedback

After implementation, we must verify that the expected results were achieved and how the relevant KPIs have developed.

Post-calculation

We review the conformity to the modeling and measure the new performance with the help of the prior model.

Improvement

Develop new ideas on the basis of the findings. We are entering, with you, into a continuous improvement process.

Beverage logistics – optimization of score tours

Challenge

- Development of new score tours for approximately 1,000 deliveries per week from two locations

- Analysis of data quality (time window, downtimes) and development of model data

- Computation of different variants of the new tours

Achieved results

- Depending on the variant, savings potential in regard to distance, route duration and route costs between 6 % and 21 %

- Depending on the variant, annual cost savings of between 110,000 EUR and 300,000 EUR

- Identification of additional optimization potential by shifting of delivery days

Retail delivery – delivery strategy analysis

Challenge

- Review of various optimization strategies for the identification of savings potential

- Computation of the potential by the use of trailers and expansion of multi-day tours

- Consideration of delivery days and time windows

Achieved results

- Identification of the best strategy in regard to multi-day deployment and trailer tours

- Weekly savings potential of approximately 22,000 EUR due to kilometer and fuel savings

- By offsetting the necessary investment in a vehicle fleet, an ROI of less than two years was achieved.

Branch delivery – delivery day optimization

Challenge

- Determination of logistic aspects of optimal delivery days for an existing branch structure

- Continuation of the existing delivery frequencies due to a fluctuation of delivery volumes

- Consideration of storage capacities of the branches during determination of the new delivery days

Achieved results

- Reduction of the weekly tour duration and driver performance – therefore identification of savings potential of approximately 2,000 EUR per week

- Uniform handling volumes and therefore uniform use of resources during the course of the week

- Reduction of the daily required vehicle fleet as no longer monetarily assessed savings potential

Retail warehouse location – optimization scenarios

Challenge

- Review whether a location should and can be closed or moved

- Development of various scenarios – with/without solution of an existing delivery assignment

- Improvement of logistics costs while keeping the delivery days and time windows

Achieved results

- Reduction of calculated logistics costs by approximately 25 % due to closing and consolidating locations on the basis of the existing customer structure

- Verification that the remaining locations are almost exactly in the logistically optimal location

- Identification of additional savings potential by reorganization of the customer/warehouse assignment