Location planning and optimization with PLANTOUR

Location counts: strategic location planning

Location planning and optimization with PLANTOUR evaluates and optimizes the assignment of customers to the depot locations as well as the cost structures and locations of the depots themselves. In addition to factors such as distance and travel time, an individual cost control function can also be integrated. The Location Optimization module answers the following questions:

- Customer assignment: From which location can the customer be serviced best?

- Location scenarios: How do the cost parameters change if additional logistics locations are made available? What number of locations is the optimum for the existing customer structure?

- Relocations and closures: How can the customers be serviced if the location of a depot site changes or is closed?

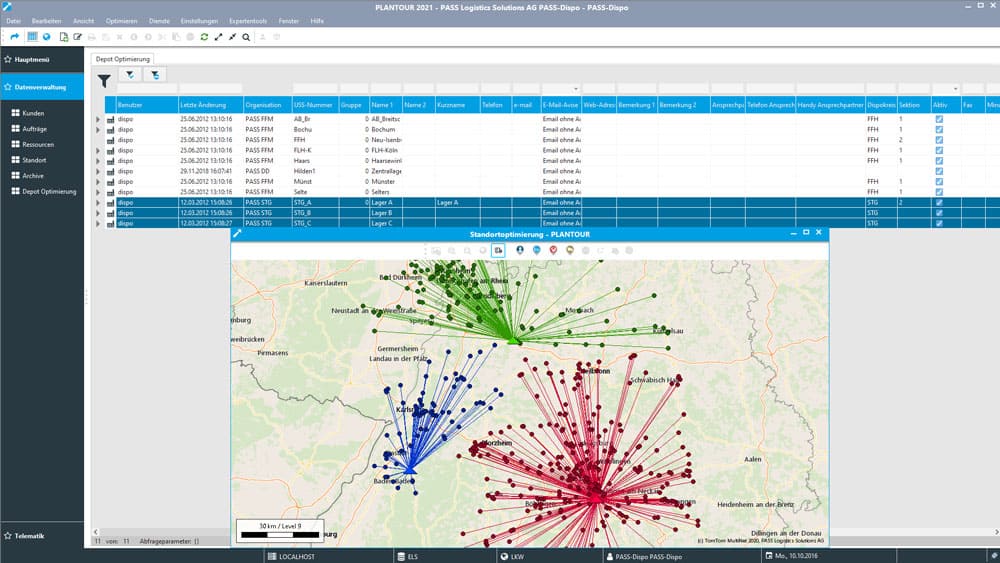

As a basis for the cost calculation of the location planning, the operative customer and depot data as well as the integrated distance calculation from our tour planning software PLANTOUR can be directly accessed. Based on trip time, distance, number of stops and the selected quantity units, the cost parameters per depot and the assignments are calculated with the help of specified default values. The result of the standard optimization can be used directly in tour planning.

Creation of simulation depots

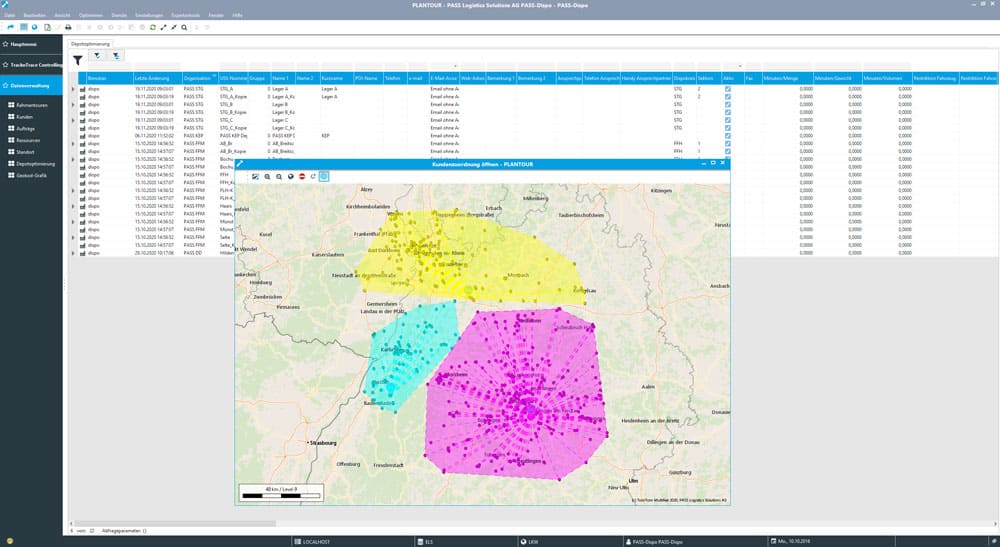

Explore different scenarios by freely simulating locations based on your actual depots.

Individual cost function

Distance, visit frequency, trip time, dynamic cost factors or fixed costs: Put together your detailed evaluation functions.

Evaluation of customer assignments

Find out which location can serve your customers best, free from operational constraints.

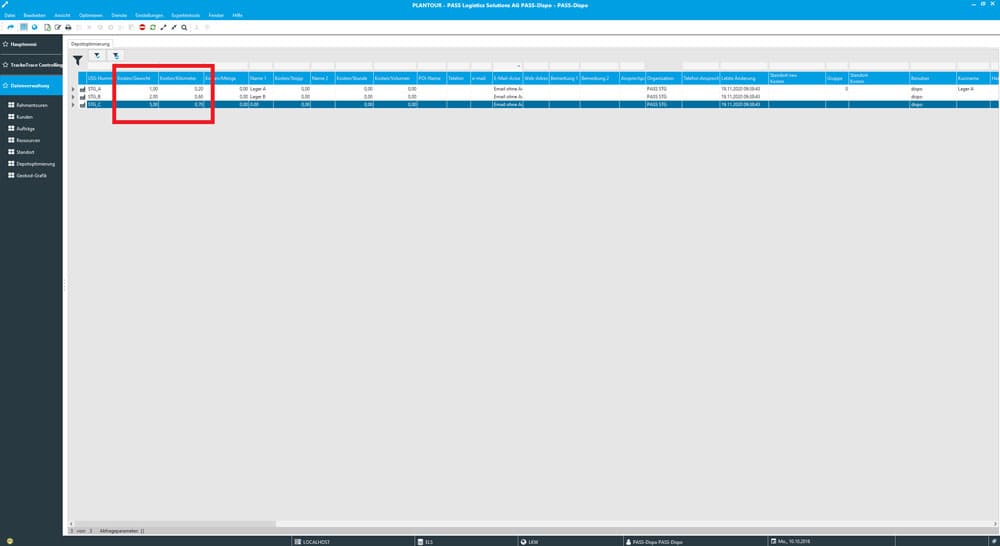

CALCULATION OF DEPOT COSTS

Let the location optimization calculate the costs of the depots with fixed and customer-dependent cost components.

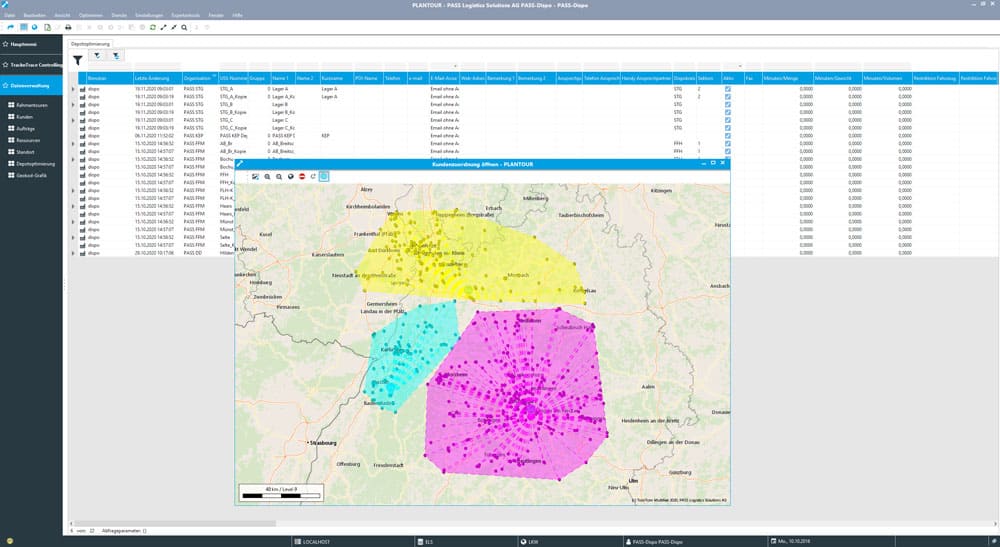

CREATION OF COMPARISON SCENARIOS

Test different options in planning and compare them afterwards. Simulate any number of location scenarios until you have found your best solution.

DIRECT INTEGRATION INTO PLANNING

Optimize your logistics locations on the basis of operational data and use your results directly in operational route planning.

Detailed reporting of current costs

Transparency regarding the current costs of location and customers helps you to make the right decisions: How much does a customer cost in delivery? Is that in ratio to sales? How much is the warehouse?

Optimizing customer assignments

Simulation from a logistical point of view: Is the customer supplied by the right depot? Or can customer value be increased by restructuring? How will customer costs develop when new customers are acquired in the region?

Economical selection of depot locations

Do you have an optimal supply network for your customers? Or can deliveries be completed quicker and more economically if you relocate your depot or open an external warehouse and optimize your location?

Review by means of simulation scenarios

What if – compare scenarios and simulate alternatives in customer assignment and location decision. Verify your decisions and use your results directly for future planning.